SPM instruction for Atlas Copco GA units

The Shock Pulse Method (SPM) was developed by SPM Instrument AB in Sweden. The primary purpose of this system has always been and continues to be monitoring the operational condition and amount of time of rolling bearings.

The main objective is to offer advanced warning of possible bearing damage, enabling planned replacements with minimal downtime and a reduced risk of machinery failure. The method has been improved over the years to check the lubrication of undamaged bearings.

This feature aids users in identifying pre-existing damage and mitigating premature bearing failures through enhanced lubrication optimization. Throughout their lifetime, bearings generate shocks in the interface between the loaded rolling element and the inner and outer raceway.

These shocks ‘ring’ the SPM transducer which outputs electric pulses proportional to the shock magnitude. A shock pulse pattern is a sequence of strong pulses (dBm level) with rapid weaker pulses (dBc level). The strong pulses can be random or rhythmic. You must be aware of:• the dBm value• the difference between dBm and dBc

Difference between shock pulse and vibration signals

Shock pulse signals are characterized by short, sharp bursts of energy, providing instant data on machine health. In contrast, vibration signals offer continuous information about equipment condition, indicating long-term trends in machinery performance. While shock pulses are more reactive to sudden changes, vibrations are better at capturing gradual variations in the system. Understanding these distinctions is crucial for accurate SPM calculations and effective maintenance strategies.

The shock pulse amplitude is due to Four basic factors:

Rolling velocity (bearing size and rpm)

Oil viscosity (thickness of the lubricating oil in the rolling interface). The oil film depends on lubricant supply and on

Alignment and preload.

The mechanical state of the bearing surfaces (roughness, stress, damage, loose metal particle).

Input data (initial value, dBi)

The effect of rolling velocity on the signal is neutralized by giving rpm and shaft diameter as input data, with ‘reasonable accuracy.’ This Set an initial value (dBi), the start of the ´normalized’ condition scale. Before every single measurement, the correct dBi-value must be introduced into the measurement device.

The carpet (dBc) and maximum (dBm) shock pulse levels are measured during FULL Load operation (max. effective working pressure) and for VSD’s, these values are given at maximum speed. For VSD’s it is always preferable to measure at maximum speed, but if not possible in the application to run at maximum speed, a speed should be selected that is reproducible in time to enable follow-up of SPM levels at, selected speed.

The conditions during the measurement should be stable. Eliminate errors due to disposition of the transducer; adapters are installed permanently at the measurement points. When doing SPM measurements, the measurement device (transducer) should be positioned on the adapter by means of a quick connector.

Evaluation (according to SPM guidelines)

The initial value and the range of the three condition zones (green – yellow – red) was empirically established by testing bearings under variable operating conditions. The maximum value places the bearing in the condition zone. The height of the carpet value dBc and delta (dBm minus dBc) allows refined bearing condition analysis and indicates lubrication quality or problems with bearing installation and alignment.

It should be noted that the real measured value is actually a dBsv value, which is normalized afterward by subtracting the corresponding. DBi-value afterward: dBn = dBsv – dBi.It should be noted that the real measured value is a dBsv value, which is normalized afterward by subtracting the corresponding dBi-value afterward: dBn = dBsv – dBi.

Technical description of SPM systems

SPM systems focus on shock pulse monitoring, a vital aspect within industrial machinery maintenance. These systems utilize advanced algorithms to analyze shock pulse signals, providing insights into equipment health. By integrating NLP techniques, SPM systems can process vast amounts of data swiftly, enabling quick identification of anomalies. The technical intricacies involve complex signal processing methodologies to ensure accurate results for preventive maintenance. Understanding the inner workings of SPM systems is essential for efficient machinery upkeep and minimizing downtime.

Calculation of the dBi-value

dBi = 20 ⋅ log(n) +12.5 ⋅ log(d) – 67.5[dBi]= dB: a norm value for bearings of the same kind, this is the value for a “perfect” bearing[n]= rpm: shaft speed[d]= mm: diameter of the bearing. For dBi values for the different machines, contact us.

Evaluation & analysis of SPM Calculation

For new units: never decide on the operating condition based on one single measurement. Instead, make at least three measurements for each SPM point every 1000 hrs or 2 months to determine an average “baseline dBm and dBc” level and assess the number of people affected. In case the first measurement is more than 15dB above the “normal dBm” values, confirm the high level after a shorter interval (500 hrs/1 month).

When the baseline dBm and dBc values are determined: if the measured dBm levels do not exceed the “normal dBm” (baseline dBm / dBc) values by more than 15dB (“ATTENTION”), the operating condition is to be considered as acceptable and measurement intervals may be kept at the maximum possible: 2000 hrs or 3 months, whatever comes first. dBm levels exceeding the “normal dBm” values by more than 15dB might indicate light but visible bearing wear.

Shorten measurement intervals to 500 hrs/1 month. dBm levels exceeding the “normal dBm” values by more than 25dB indicate developed bearing wear. Prepare overhaul. It is recommended to exchange the element as soon as measured dBm levels reach 30dB above the “normal dBm” value. This is the “ALARM” level. When the dBc value increases, while the dBm value is almost constant, the lubrication of the bearings is getting worse, either the quality of lubricant or amount of lubricant.

Notes:

1. In case the list with dBi values is not on hand, measurements can still be done (and are useful) by setting dBi = 0 db.

In this case, the absolute shock pulse value is measured, and the normalized value can be derived from the measurement by subtracting the correct dBi value from the measured absolute shock pulse level.

e.g.:

dBm = 50 dBsv (measured with dBi = 0 dB) → dBm = 30 dBn (normalized) when dBi = 20 dB2.

Also, in case the wrong dBi value is set when doing the measurement, the measurement is not lost.

The correct normalized value can be derived from the measurement by adding the wrongly set dBi value and then subtracting the correct dBi value

dBm = 30 dBsv (measured with dBi = 10 dB) → dBm = 20 dBn (correct normalized level) when correct dBi = 20 dB3.

It is advised to do the first SPM measurement at start-up of the machine.

Processing and analyzing shock pulse signals

Processing and analyzing shock pulse monitoring signals involve extracting meaningful insights from the data captured. It necessitates deep dives into the shock pulse monitoring (SPM) results to uncover patterns, anomalies, and potential issues. By utilizing advanced algorithms, NLP techniques, and statistical models, analysts can decode the signals efficiently. Understanding the nuances within the signals is crucial for accurate diagnostics and predictive maintenance strategies. Efficient processing and analysis can significantly enhance equipment reliability and minimize downtime.

Calculation of data not mentioned on the data sheet.

For VSD’s, data for other element speeds can be interpolated to obtain an “indicative” value (). Also, for other pressures, interpolation can be used to get an “indicative” value ()

SPM measurements for VSD compressors

Rpm1, 2: Given motor speed on the data sheet.

Rpm: at which motor speed the dB-value must be calculated, this value should lie between Rpm1 and Rpm2

dBx1,2: the dB-value at the respective motor speed (dBm or dBc)

dBx: the wanted dB-value at a certain motor speed, Rpm.

SPM measurements for VSD compressors for RPM

Pressure1,2: Given pressure on the data sheet, Pressure: at which pressure the dB-value must be calculated, this value should be lying between Pressure1 and Pressure2(*)

Note:

The relationship between speed or pressure and dB values is not linear and therefore using the above equation will only give approximate values. Therefore, it is advised to measure SPM at full load operation as stated before and for VSD’s at full speed. Especially for VSD’s, if customer installation does not allow it to operate at full speed, it is advised to consult us.

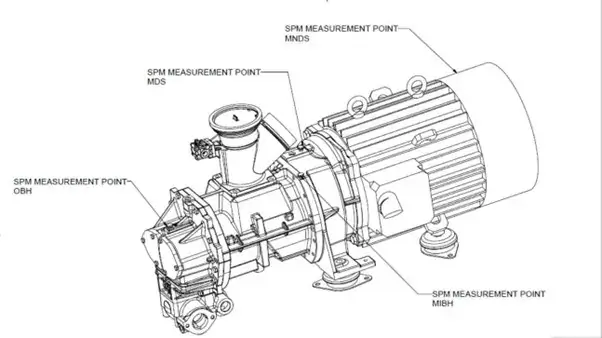

Nomenclature

· MOBH Male outlet bearing housing.

· FOBH Female outlet bearing housing.

· MIBH Male inlet bearing housing.

· FIBH Female inlet bearing housing.

· OBH Outlet bearing housing.

· MDS Motor drive side

· MNDS Motor non-drive side

Nomenclature for SPM Measurement

What is SPM (Shock Pulse Measurement)?

Shock Pulse Measurement, commonly referred to as SPM, is a technique used to monitor the condition of rotating machinery, such as compressors in Atlas Copco GA Units. SPM works by analyzing the shock pulses generated by the machinery during operation, providing valuable insights into the health and performance of the equipment. By measuring and interpreting these shock pulses, maintenance professionals can detect potential issues early on and take corrective actions to prevent costly breakdowns.