Shaft alignment is important for machine maintenance to make sure machine parts are aligned correctly and to reduce damage. Aligning machines properly reduces the risk of misalignment, which can cause various alignment issues that affect the performance and lifespan of the machine. Laser shaft alignment systems have greatly improved the process of aligning machinery, offering more precision and efficiency compared to traditional methods. These systems, along with other laser shaft alignment tools, have become essential in addressing the complex demands of modern machinery.

Tools that adapt to different machinery types and configurations are crucial for effective alignment. There are tools and techniques available to address machine alignment challenges. Laser shaft alignment tools are highly accurate and easy to use, which makes them a top choice for maintenance engineers worldwide. Using advanced tools for pump and motor alignment has benefits like saving energy, reducing downtimes, and increasing operational efficiency.

Understanding the Fundamentals of Shaft Alignment

Types of Misalignments

At its core, shaft alignment is about ensuring that the rotational axes of two or more shafts are perfectly aligned when the machines are at operating temperature. The process involves using shaft alignment systems to identify and correct misalignment between connected machines. Laser shaft alignment systems, popularly known as laser alignment systems, have become the standard due to their precision and reliability. Adaptive alignment systems enhance the alignment process even further by automatically adjusting to the specific conditions of each alignment task. This simplifies the process, guarantees superior alignment accuracy, and effectively mitigates alignment issues.

The Importance of Accurate Shaft Alignment in Maintenance Engineering

Accurate shaft alignment plays a pivotal role in maintenance engineering, directly impacting machinery health and operational efficiency. By harnessing the power of shaft alignment systems, particularly laser shaft alignment systems and laser alignment systems, one can achieve meticulous adjustments in motors and pumps. This not only enhances the longevity of the machinery but also ensures optimal performance. Adaptive alignment systems take it a step further by automatically adjusting to various alignment challenges, ensuring optimal alignment with minimal effort. These technologies, especially state-of-the-art laser alignment systems, play a vital role in preserving equipment reliability, minimizing downtime, and guaranteeing the safety and productivity of industrial operations.

Common Signs and Symptoms of Shaft Misalignment

“Prompt identification of shaft misalignment in pumps and motors is essential for timely intervention and prevention of further machinery damage.” Various indicators can signal the presence of misalignment issues.Sign/Symptom of Misalignment Resulting in Failure – Increased vibration Premature wear of bearings and seals Premature wear Reduced component lifespan Bearing failure Unexpected machinery breakdowns Unusual noise Internal distress and misalignment Excessive heat Overloading and inefficiency in operation Energy consumption Higher operational costs due to inefficiency

Delving Deep into Shaft Misalignment

Understanding shaft misalignment, which is the process of aligning shafts in rotating machinery to reduce wear and tear, requires a thorough exploration of the factors contributing to this common issue. Misalignment can arise from a variety of sources, affecting the performance and longevity of machinery. Shaft alignment systems, such as laser shaft alignment systems like SKF alignment kits, are used to accurately diagnose and fix misalignment issues. These advanced tools are very accurate and can effectively identify and fix misalignment issues, protecting machinery from the negative effects of misalignment.

Identifying the Root Causes of Misalignment in Rotating Equipment

Identifying the root causes of shaft misalignment involves a thorough analysis of alignment measurements, which can reveal issues like pipe strain and discrepancies in shaft center lines. Understanding the condition of an asset and these underlying factors is crucial for effective alignment correction. Maintenance engineers can use pinpointed solutions to accurately realign shafts, ensuring smooth and efficient machinery operation.

The Impact of Misalignment on Machinery and Operations

The impact of misalignment on machinery and operations cannot be overstated. Misaligned machinery often suffers from increased wear, energy inefficiency, and a higher likelihood of premature failure. By employing shaft alignment systems, including laser shaft alignment systems and laser alignment systems, maintenance teams can mitigate these risks. These advanced technologies enable precise alignment adjustments, significantly improving machinery performance and operational reliability.

Methods and Techniques for Effective Shaft Alignment

Effective shaft alignment involves a combination of methods and techniques tailored to the specific needs of the machinery being serviced, including versatile laser systems and flexible couplings. Laser alignment tools, such as SKF laser alignment solutions, are now widely preferred because they are precise and easy to use. Old methods like dial indicators and straight edges are still used, but they are being replaced by new advanced technologies. The method chosen depends on the task’s specific requirements, such as the type of machinery and the severity of misalignment.

Vibration Analysis as a Diagnostic Tool for Shaft Alignment

Accurate shaft alignment is crucial in maintenance engineering to prevent issues like vibration, downtime, and machinery breakdowns. By using techniques such as vibration analysis and thermography, the root causes of misalignment can be identified early. This proactive approach helps in maintaining proper alignment, reducing energy consumption, and extending the service life of equipment. Investing in quality shaft alignment tools and training ensures precise alignment, minimizing scrap rates and labor costs in the long run.

Employing Thermography in Shaft Alignment

Proper alignment of the machine, particularly shaft alignment, is pivotal for operational efficiency and longevity in rotating equipment. Misalignment can lead to increased energy consumption, mechanical stress, and component wear. Detection methods like vibration analysis and thermography aid in diagnosing misalignment issues. By utilizing advanced technologies such as laser alignment tools, maintenance engineers can ensure precise alignment of the machine, reducing downtime and optimizing the service life of machinery. Investing in quality alignment tools and training contributes to overall equipment reliability and performance.

The Role of Oil Analysis in Maintaining Shaft Alignment

Accurate shaft alignment is crucial in maintenance engineering to prevent machinery breakdowns and optimize operations. Signs of misalignment include unusual vibrations and increased energy consumption. Identifying misalignment root causes involves factors like human error or environmental conditions. Misalignment impacts machinery service life, labor costs, and scrap rates. Using vibration analysis techniques and thermography aids in alignment checks. Proper alignment ensures precision in machinery operation, minimizing downtime and enhancing overall efficiency.

Overview of Different Shaft Alignment Methods:

Improved machinery lifespan and decreased flexible coupling wear.

Types of shaft misalignment

There are two types of misalignment – angular misalignment and offset misalignment – and they may occur in horizontal and vertical planes, including horizontal angle misalignment.

The distance between the shaft centers of rotation, typically measured at the coupling center, is called offset misalignment, or parallel misalignment.

Parallel Misalignment and Angular misalignment

It is usually expressed in mils (where 1 mil = 0.001 in.).Angular misalignment occurs when the slope of one shaft, typically the movable machine, differs from the slope of the other shaft, typically the stationary machine. This difference is sometimes referred to as gap, face, or simply angularity.

This measurement is like measuring the slope of a roof (i.e., rise/run). Mils are used to measure the rise, while inches are used to measure the run (distance along the shaft). Mils per inch are used to measure angular misalignment.

Angular and parallel misalignment manifests itself in the following interrelated problems:

• Increased vibration.

• Increased energy loss and high-power consumption.

• Increased load on bearings, seals, and other mechanical components

• Reduced production capacity

• Reduced product quality

• Reduced life span

• Coupling failures

• Increased repair time

According to conservative surveys conducted across various industries in the past decade, poor alignment is directly responsible for 50% of all machine breakdowns. Some surveys have shown that as much as 90% of machines are running beyond their recommended tolerances.

Choose an Alignment Method

Shaft alignment system, alignment tools (Brackets, Dials, or laser shaft alignment tool)

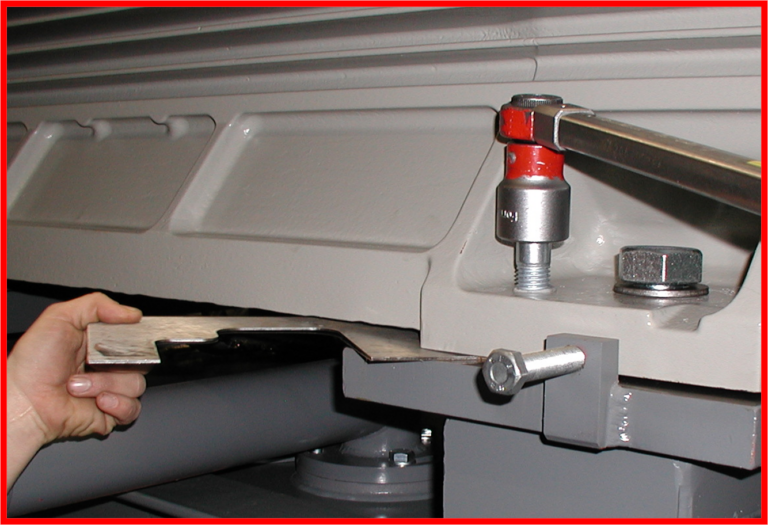

Choose the appropriate alignment technique for your equipment based on the available tools and alignment preparation. Brackets and arms are essential for installing measuring equipment in various alignment procedures, including the use of face dial indicators. As arms get longer, they are more likely to sag, which can lead to measuring mistakes if not considered.

Laser systems with sensors are more accurate and less prone to sagging. It can be used to correct both horizontal misalignment and vertical misalignment.

RIM AND FACE DIAL METHOD

The traditional and widely applied dial indicator technique is the Rim and Face technique. This is ideal for hubs with a short distance between shaft ends and large diameter. The method requires use of dial gauges horizontally and vertically to achieve correct shaft alignment.

Rim and face method of shaft alignment

Alignment measurements of the driver and the driven piece of equipment may be offset as per manufacturer.

Advantages of RIM and Face Method:

· Rotating one shaft is all that is required.· This method is simpler than others when trying to see the placement of the shaft.

Disadvantages of RIM and Face Method:

If there is any axial float, it is difficult to obtain face readings.

· Typically, the user must remove the coupling.· Graphical calculations are more complicated than other methods.· If the hub is not round or flat and square to the shaft, it will affect the readings.

Method 2 — Reverse Dial Method

For most alignments, reverse Dial (indicator) is the most optimal method.

Reverse dial method of alignment

Advantages of the Reverse Dial Method:

· In general, it is more accurate than the face and periphery methods.· The readings are not affected by axial float, out-of-roundness, or out-of-squareness in the hub, ensuring better rotary-axis parallelism.· Graphs can be plotted more easily than other methods.· Measuring can be done with the coupling installed.

Disadvantages of the Reverse Dial Method:

· The end user must rotate shafts.· The method is not accurate for shafts that are tightly coupled.

Laser Shaft Alignment: A Modern Approach

Laser shaft alignment represents a modern approach to addressing alignment challenges, offering high precision and efficiency through laser alignment technology. This method utilizes laser beams to measure misalignment accurately, allowing for quick and precise adjustments. Using laser technology for alignment tasks saves time and effort, making it a great option for maintenance engineers wanting to improve machinery performance and reliability.

Laser alignment method for rotating machines

Traditional Vs. Advanced Alignment Techniques

The shift from dial indicators to laser alignment tools signifies a major breakthrough in maintenance engineering. Traditional methods of motor and pump alignment have been effective for many years, but they typically take longer and require more expertise to achieve accurate machinery alignment. In contrast, laser alignment tools offer a level of precision and ease of use that significantly streamlines the alignment process. This transition to advanced techniques represents a move towards more efficient, accurate, and reliable maintenance practices.

How to Choose the Right Alignment Method for Your Needs

Choosing the right alignment method is vital for ensuring the longevity and efficiency of machinery. When choosing between alignment methods like the dial indicator method and more advanced techniques, consider the machinery’s specifications, precision needed, and operating environment. For simple applications, the dial indicator method works well. However, laser alignment is better for complex systems because it is more accurate and faster. To make the best choice for your situation, it is important to understand the specific needs of your machinery and the capabilities of different alignment methods.

Practical Steps for Shaft Alignment and Misalignment Correction

Proper shaft alignment is crucial for the smooth operation of machinery. Alignment is done in two directions: horizontal and vertical. Shims are often used to make small adjustments and achieve the desired alignment. Initially, a rough alignment is conducted to bring the shafts into a closer approximation of their final position. Shaft alignment systems are used to make sure the machine runs efficiently by aligning it in both horizontal and vertical planes. Regular alignment checks are necessary to maintain this efficiency and prevent downtime.

Pre-Alignment Checks and Preparation

Before beginning the alignment, pre-alignment checks are essential to ensure accurate shaft alignment in rotating machinery. Laser beams are used to measure the alignment of the shaft or coupling before making any adjustments. This step is critical for identifying any potential issues that could affect the alignment process and the machinery’s operation.

Creating a Comprehensive Pre-Alignment Checklist

A comprehensive pre-alignment checklist is a foundational step in preparing for alignment. It should include an examination of pipe strain, ensuring it does not affect the machine setup. The checklist must also define alignment tolerances based on the chosen alignment method to guide the alignment process accurately. By preparing well, you can avoid common problems during the alignment process and make sure the alignment is precise both vertically and horizontally.

Step-by-Step Guide to Correcting Shaft Misalignment

Correcting shaft misalignment involves a systematic approach using shaft alignment systems. This process is essential for the optimal performance of rotating machinery. Following a structured method ensures that technicians achieve proper alignment and align machinery shafts correctly, which is crucial for its longevity and efficiency.

Creating a Comprehensive Pre-Alignment Checklist

Laser shaft alignment systems offer unmatched accuracy in shaft alignment, especially when combined with SKF kits for optimal machinery performance. These systems generate accurate measurements that are crucial for aligning the shafts to a degree that manual methods cannot achieve. Using them helps machines operate better, reducing damage and maintenance costs, and making machines last longer.

Maintenance Engineering Perspectives on Shaft Alignment

From a maintenance engineering perspective, the emphasis on using advanced shaft alignment systems for pumps and motors is significant. These systems not only offer precision but also contribute to a deeper understanding of machinery behavior under various operational conditions. This knowledge is crucial for predictive maintenance strategies, aiming to anticipate and mitigate potential failures before they occur.

The Role of Shaft Alignment in Preventing Equipment Downtime

Proper shaft alignment plays a crucial role in preventing equipment downtime. Misalignment can lead to increased vibration, bearing failures, and other issues that result in unplanned stops and costly repairs. Aligning the shafts correctly in motor and pump systems helps maintenance engineers prevent downtime and improve production efficiency.

What Does a Regular Shaft Alignment Check Contribute to Extended Machinery Life?

Regular shaft alignment checks are essential for extending the life of machinery, and they often require modern laser alignment tools to ensure optimal accuracy. These checks can identify misalignment before they cause severe damage, allowing for corrective action to be taken promptly. Regular maintenance, including alignment checks and shim kit corrections, prevents breakdowns and extends the machinery’s lifespan by making sure all components work well together.

Advanced Technologies in Shaft Alignment

The advancement of technologies in shaft alignment, particularly the development of laser shaft alignment tools, has revolutionized maintenance engineering. These tools provide high precision and efficiency, improving the process of aligning shafts and thereby enhancing machinery performance and reliability.

Motor shims used for alignment

The Evolution of Laser Shaft Alignment Tools

Laser shaft alignment tools have evolved to address complex alignment challenges, such as misalignment and offset misalignment, specifically in vertically oriented shafts. These tools can be used in different situations and provide solutions that cannot be achieved with manual methods. They represent a significant advancement in machine alignment technology.

Adaptive Laser Shaft Alignment: A Game-Changer in Maintenance Engineering

Adaptive laser shaft alignment represents a breakthrough in maintenance engineering, particularly when integrated with the practice of identifying and fixing misalignment. These tools have improved machine alignment by allowing adjustments for different types of misalignment, ensuring precise alignment for a variety of machinery. Laser shaft alignment tools are very precise and adaptable, and when combined with shims for adjustments, they are essential for modern maintenance. They help ensure maximum equipment efficiency and reliability.

Accessing Remote Monitoring and Support for Shaft Alignment

Ensuring proper shaft alignment is essential for maintaining rotating equipment. This method enables experts to collect and analyze data in real-time for motor and pump maintenance, so they can provide guidance and solutions without needing to be there in person. These remote capabilities make sure that support is available even in tough environments, allowing timely interventions to keep shaft misalignment within acceptable limits.

Tips and Best Practices for Shaft Alignment

Achieving proper shaft alignment in pump and motor systems requires following best practices, implementing helpful tips, and utilizing the correct measurement technique. It is vital to always verify that the equipment is in a proper state before beginning the alignment process. This means looking for loose base bolts or wear in the coupling, which could impact the alignment’s accuracy. Training and using precision tools, like laser shaft alignment tools and hydraulic kits, can greatly enhance the effectiveness and accuracy of the process.

When to Perform Shaft Alignment: Understanding the Best Timing

Optimal timing for performing shaft alignment is crucial for maximizing equipment efficiency and lifespan. Alignment should be done after installing or moving machinery, after major repairs, and as part of regular maintenance. Unusual vibrations or noise in pump and motor systems may be early signs of wear and tear. They can indicate the need to check and correct the alignment promptly. This initiative-taking approach ensures that machinery operates within its designed specifications, preventing premature failures.

Avoiding Common Pitfalls in Shaft Alignment Procedures

Avoiding common pitfalls in shaft alignment procedures requires keen diligence and a thorough understanding of the machinery involved. One major mistake is neglecting soft foot correction, which can lead to inaccurate alignments and ongoing issues with machine performance. One mistake is thinking that new installations don’t need alignment checks. This misconception can lead to equipment stress and damage. It’s important to make sure that one shaft is aligned accurately with another. Proper training and the use of advanced alignment tools are crucial for avoiding these and other common errors.

The Future of Shaft Alignment in Rotating Equipment Maintenance

“The future of shaft alignment in rotating equipment maintenance is advancing towards greater accuracy and productivity.” As industries continue to evolve, the demand for minimal downtime and maximized equipment lifespan is driving innovations in alignment technologies. Understanding how to align shafts and applying it to rotating equipment is important. The methods and tools used will become more advanced, using real-time data analysis and predictive maintenance strategies.

Innovations on the Horizon: Next-Generation Alignment Systems

Next-generation alignment systems promise groundbreaking improvements in the field of maintenance engineering. These innovations include the integration of AI and machine learning algorithms capable of predicting misalignment issues before they escalate. Advances in sensor technology will provide more accurate alignment measurements, significantly reducing the time, effort needed for alignments, and scrap rates. These technologies will enable maintenance teams to achieve near-perfect alignment, minimizing equipment wear and extending machinery life.

Integrating Shaft Alignment into Predictive Maintenance Strategies

Integrating shaft alignment into predictive maintenance strategies for pump and motor systems represents a proactive approach in equipment maintenance, highlighting the significance of precise calculations and evaluations to ensure alignment and mitigate misalignment. By continually checking alignment and using predictive analytics, maintenance teams can predict and fix misalignment problems before they cause equipment failure. This integration improves machinery reliability and performance and reduces maintenance costs by preventing unexpected downtime and extending equipment service life.

Navigating Challenges in Shaft Alignment

Navigating the challenges in shaft alignment requires a blend of experience, knowledge, and the right tools. Complex alignment scenarios frequently result from machinery configurations or challenging operational environments, posing significant obstacles. However, the use of advanced tools, particularly laser shaft alignment tools like those from Fluke, has proven to be instrumental in overcoming these challenges. These tools offer precision and versatility, enabling maintenance professionals to achieve optimal alignment even in the most demanding situations.

Addressing Complex Alignment Scenarios with Advanced Tools

Addressing complex alignment scenarios in motor and pump systems demands a comprehensive approach that incorporates advanced tools and techniques, including precise alignment systems, emphasizing the importance of accuracy. Laser shaft alignment tools have revolutionized the process, offering a level of accuracy that traditional methods cannot match. These tools can manage a wide range of alignment challenges, from standard configurations to those involving intricate machinery setups. Their precision and efficiency make them indispensable for ensuring machinery operates within its optimal parameters.

Overcoming Obstacles in Shaft Alignment through Training and Education

Overcoming obstacles in shaft alignment is significantly aided by ongoing training and education in modern laser alignment techniques. As machinery and alignment technologies become more complex, there is a growing need for skilled professionals who can handle these challenges. Training programs focus on teaching the latest alignment techniques and tools, especially laser shaft alignment tools. They assist maintenance teams in acquiring the necessary knowledge and skills to ensure precise and efficient alignments. This enhances machinery reliability and performance.

Elevating Your Maintenance Strategy with Proper Shaft Alignment

Elevating your maintenance strategy involves incorporating proper shaft alignment as a core component, often utilizing single-laser systems for improved precision. This approach not only ensures the smooth operation of machinery but also significantly extends the lifespan of equipment components. By focusing on accurate shaft alignment and investing in good tools and training, organizations can improve equipment reliability and performance, leading to less downtime and lower maintenance costs.

The Benefits of Investing in Quality Shaft Alignment Tools and Training

Investing in quality shaft alignment tools and training offers substantial benefits, from enhanced equipment performance to extended machinery life. High-quality laser shaft alignment tools are very accurate. They enable precise alignments that safeguard machine components against damage while reducing labor costs. Training and tools help maintenance teams perform alignments better, making sure machinery works well and reducing downtime.

What is machine alignment and why is it important in industrial settings?

Machine alignment is the precise adjustment of machine components to ensure they are in proper position relative to each other. In industrial settings, accurate alignment is crucial for optimal machine performance, reducing wear and tear, minimizing downtime, and enhancing overall efficiency and productivity.

Conclusion: Maximizing Equipment Efficiency and Reliability Through Precision Shaft Alignment

Maximizing equipment efficiency and reliability through precision shaft alignment is essential for any maintenance strategy. By following basic principles and using advanced tools like adaptive laser shaft alignment systems, maintenance professionals can ensure that machinery shafts are parallel, thus maintaining continuous operation by reducing damage on bearings, seals, and other machine parts. The precision approach extends machinery life and improves operational efficiency, showing how important alignment is for maintaining high-performing mechanical systems.

Contact Turbo Airtech today for expert Alignment Services.