Compressor Valves – What They Are & Why They’re Important

Do you know what a compressor control valve is and how it works? If not, you’re not alone. But knowing about compressor control valves is essential if you own or work on a compressor, as they play an important role in loading and unloading cycles.

We’ll outline the basics of these valves and explain their benefits. We’ll also discuss how they work and why it’s important to have one on your compressor. Finally, we’ll provide an overview of the installation process for these valves, so that you can be sure your compressor is equipped with the proper control valve.

What is a compressor control valve?

Inlet Guide Vanes (IGV)

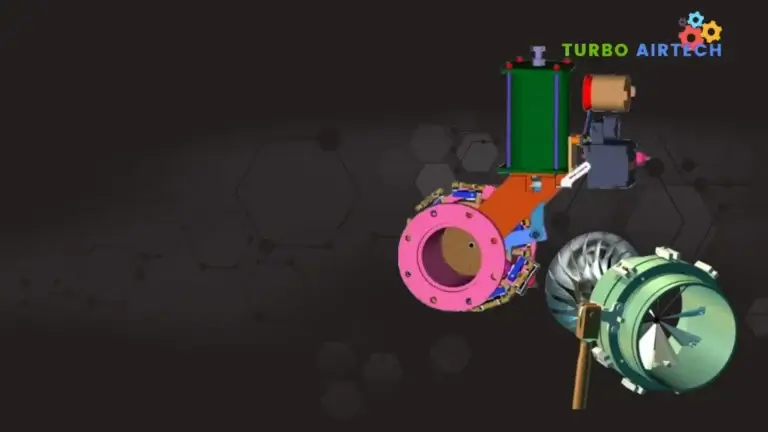

Primary control valves consist of the inlet guide vane assembly that determines how much air is drawn into the compressor and is the primary anti surge valve control, and the compressor discharge valve that determines how much discharge air leaves the compressor into the compressed air system.

Blow off Valve (BOV) in Centrifugal Compressor

In a centrifugal compressor, the blow off valve (BOV) plays a crucial role in maintaining optimal performance and efficiency. The BOV is responsible for releasing excess pressure that builds up in the compressor system, preventing any potential damage or malfunctions. By diverting the excess air or gas to the atmosphere, the BOV helps regulate the flow and pressure within the compressor, ensuring smooth operation and preventing any overloading. It is important to understand the functions and types of blow off valves in centrifugal compressors to ensure the proper functioning of the system.

In addition, there are two discharge control valves: the discharge check valve that prevents air from flowing backwards through the compressor; and the customer-supplied discharge block valve that isolates the compressor from the air supply during compressor shutdown. Inspect them periodically for wear and tear, and make sure they are in working order by checking for leaks, noise, and any signs of condensate accumulation.

Benefits of having a compressor control valve

Compressor control valves are essential for a healthy compressed air system. They help to regulate pressures, flow and temperatures of different essential systems inside a compressor. For example, inlet guide vane assembly determines how much air is drawn into the compressor (air Compressor supply), acting as primary anti surge control, and the compressor blow off valve that determines how much discharge air leaves the compressor.

Besides these main compressor control valves, there are other control valves in the system. For example, the discharge check valve, placed at the compressor head, serves a very important function of preventing any backflow of air into the compressors, safeguarding it from surge conditions.

The block valve in the discharge line ensures compressor isolation in case of shutdown and maintenance activities.Control valves in oil systems ensure proper pressure and flow for the bearings of the compressor and the motor. A control valve in the oil mist line ensures that the oil vapors are removed, and a proper vacuum is maintained inside the oil tank for safe compressor operation.

How do compressor control valves work?

Most of the control valves are controlled either electrically (electronic control valve) or pneumatically through a compressor controller using a control logic to ensure proper operation, advanced noise control as per control philosophy, including OEM specifications. Contact Turbo Airtech to learn more.

Butterfly Valve Basics for Compressor Control

Butterfly valves are widely utilized in various industrial applications, including compressor systems, due to their simple and effective design. In compressors, these valves typically function as air inlet valves, regulating the airflow into the system. They can be either electronically or pneumatically actuated, allowing for precise control over the air intake. As the butterfly valve closes, it restricts the inlet flow, consequently limiting the compressor’s ability to generate both pressure and airflow. This dynamic is crucial for optimizing performance and preventing overload situations. Furthermore, while butterfly valves are efficient for many applications, they may not provide as tight a seal as ball valves, making them more suitable for specific operational conditions where a complete seal is less critical.

A key function of butterfly valves within compressor control systems is to facilitate smooth modulation during varying operational demands. This modulation is essential in maintaining the desired pressure levels and ensuring that the compressor operates efficiently without unnecessary energy consumption. By enabling the compressor to adjust its airflow based on system requirements, butterfly valves play a pivotal role in optimizing the performance of the entire compressor setup, contributing to its longevity and reliability.

Understanding the Role of Ball Valves in Compressor Systems

Ball valves are another critical component in compressor systems, known for their reliable performance and ability to create a tight seal. Unlike butterfly valves, which utilize a circular plate for regulation, ball valves consist of a spherical disc with a hole through it that allows for precise flow control. This design not only enables ball valves to prevent leaks more effectively but also minimizes pressure drops, making them ideal for applications requiring high flow rates. In the context of compressor systems, ball valves are predominantly used for the blow-off function, where they ensure that excess pressure is safely vented when necessary.

Moreover, ball valves serve as check valves in certain configurations, ensuring that air or gas does not flow back into the compressor when it is not in operation. This backflow prevention is crucial for maintaining the integrity of the system and avoiding potential damage. Typically made of brass or other durable materials, ball valves, along with piston valves, are favored for their longevity and resistance to wear and tear under high-pressure conditions. Understanding the role of ball valves in compressor systems is essential for maintaining operational efficiency and safeguarding against potential issues that could arise from improper flow regulation.

Overview of the installation of a compressor control valve

Conclusion

Compressor control valves and drain valves are important components of any compressed air system. By understanding their function and installation, you can ensure that your compressed air system/air conditioning system is functioning optimally. Make sure to keep your compressor control valve in good condition by regularly checking the seals, compressor control solenoid valves, vibration, internal pressure, compressor electronic control valve and controls with the help of compressor experts.

Turbo Airtech specializes in the full service, including air compressor services, repair, and overhaul of centrifugal compressors. In order to avoid losing time due to downtime, we always try to measure our turnaround in weeks, not months. If you would like to learn more about our services or to speak with a centrifugal compressor repair specialist.