What Is An Air Compressor Cooler?

Air compressor aftercoolers are essential components of compressed air solutions that cool the compressed air within a system after compression. When air is compressed, it can generate significant heat, which needs to be reduced to prevent damage to sensitive equipment downstream. Aftercooler cools the air typically to compressed air within 20-30 degrees of the ambient air, making it suitable for various applications.

There are two main types: either water or air-cooled aftercoolers. Air-cooled aftercoolers use metal fin designs to dissipate heat, while water-cooled versions utilize water and air exchange. An intercooler is a device that operates between compression stages – intercooler cools the air during the compression process, improving the efficiency of the compressor. Intercoolers are used in multistage compressors to enhance performance and reduce operating temperatures.

Leading manufacturers like Atlas Copco provide reliable cooling solutions with excellent durability and energy-efficient designs. Compressor experts recommend regular maintenance to prevent condensate buildup in the tubing. Many aftermarket options are available, but consulting with the best supplier will help tailor the right air treatment solution for your specific needs. Proper cooling ensures that when air is released from the system, it’s at an optimal temperature for use.

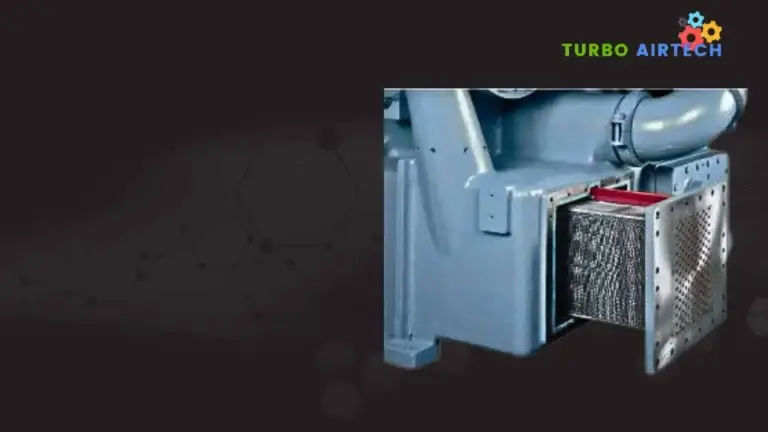

Compressor cooler

Air compressor coolers (compressor intercoolers, air compressor After cooler, & oil coolers) are mechanical heat exchangers used to remove air-flow heat and moisture to produce cool, dry air suitable for use in energy efficiency for air-powered equipment. Basically, a compressor air cooler serves the following purposes:

The cool compressor discharges air or inter-stage temperature in a

Air compressors after cooling reduce the moisture content of compressed air systems.

Compressed air

The air compressor oil cooler keeps the compressor oil cool.

The cooler

Inter cooler

The cooler for the air compressor reduces the load on downstream equipment like the air dryer.

Why are industrial air coolers required?

Type of Compressor | Approx Outlet Temperature |

|---|---|

Oil-Injected Rotary Screw | 180 |

Oil-Free Rotary Screw | 300 |

2-Stage Reciprocating | 250 |

Turbo Air Centrifugal | 180 |

Air that is too hot is usually not appropriate for use in air-operated equipment because it degrades lubrication and seal materials. Moisture vapor contained in hot air can also cause rust, scale build-up, the loss of lubricant, and freezing issues when it condenses.

Atmospheric air contains water vapor, which becomes more concentrated when the air is drawn into a compressor and pressurized. Since the air after compression is extremely hot, the moisture remains in a vapor state, above the dew point temperature.

Dew point is the temperature at which air becomes saturated when it is capable of holding 100 percent of its capacity to hold water vapor. In general, the air can hold twice as much moisture in a vapor state as it can below the dew point for every 20°F rise in temperature.

With a compressor inter cooler and after cooler, the dew point drops and water vapor condenses. The water vapor in the air will become droplets if the amount of moisture in the air exceeds the dew point. Without an air compressor cooling system, a 200 CFM air compressor operating at 100 PSI may result in up to 45 gallons of water every day in the compressed air cooling system.

Compressor Intercooler

Types of air compressor coolers:

Generally, an air compressor cooler can be classified as air-cooled or water-cooled.

Air-Cooled compressed air coolers

The hot compressed air is cooled by ambient inlet air in air-cooled compressed air coolers. A motor-driven fan forces ambient air over the cooler as compressed air travels through an air-cooled cooler. It is designed with a spiral-finned tube coil or with a plate-finned coil design.

Compressed air is cooled by ambient air. An air-cooled After cooler is usually sized to bring the temperature of compressed air to within 15 °F to 20 °F of ambient cooling air temperature, also called approach temperature.

When compressed air cools, up to 75% of the water vapor condenses into a liquid, which needs to be drained. The liquid moisture and solids in compressed air are removed mechanically from the air using a moisture separator installed at the discharge of the After cooler. These separators ensure the highest level of clean compressed air, with moisture and solids collected at the bottom of the moisture separator using centrifuges and baffle plates, in some cases. Moisture should then be removed through an automatic drain.

Water-Cooled Air Compressor Cooler

The Significance of Drying Compressed Air

Moisture in compressed air systems can lead to numerous operational challenges, making the drying process an essential component of air compression. When air is compressed, the water vapor present in the atmospheric air becomes concentrated, leading to the formation of condensate as the temperature of compressed air decreases. This condensate can cause significant damage to equipment and increase the presence of harmful contaminants, reducing the efficiency of the system. By efficiently cooling the compressed air, it’s possible to lower the temperature and subsequently the dew point, allowing for effective moisture removal.

Drying compressed air not only prevents corrosion and freezing in pneumatic tools but also enhances the overall quality of the air. Maintaining a cooler temperature of compressed air helps to reduce the moisture content, which is critical in preventing breakdowns associated with excessive humidity. Implementing proper drying techniques ensures the longevity of equipment and improves operational reliability, making it a vital aspect of maintaining an efficient air compressor system.

Why it’s Critical to Dry Compressed Air

Drying compressed air is crucial for maintaining the integrity and performance of various pneumatic systems. One of the primary reasons for this necessity is to avoid breakdowns caused by moisture-related issues and mechanical malfunctions. When moisture condenses within air lines, it can lead to rust and corrosion, ultimately damaging sensitive components and causing costly repairs. Additionally, excess moisture can contaminate the air supply, compromising the quality of the end product and potentially resulting in product rejection.

Moreover, contaminants introduced by moisture can lead to inefficiencies in air-powered tools and systems, resulting in increased energy consumption and operational costs. When air is properly dried, it reduces the risk of freezing in colder environments, which can cause blockages and hamper system performance. Therefore, implementing effective drying solutions is essential for ensuring smooth operations and minimizing maintenance interruptions.

In summary, the significance of drying compressed air cannot be overstated. It plays a vital role in protecting equipment, enhancing operational efficiency, and maintaining the quality of the compressed air. By investing in proper air drying solutions, businesses can significantly reduce the risk of breakdowns and extend the lifespan of their pneumatic systems.

Cooler Bundle for air compressor intercooler and aftercooler

Unlike air-cooled after coolers, water-cooled air compressor coolers are installed in stationary compressor installations where there is access to cooling water. As a cooling medium, water has several advantages:

There are no seasonal temperature fluctuations, which is common for inlet air

It is cost-effective and readily available.

It can approach ambient air temperatures efficiently, eliminating

Condensation downstream and cooling compressed air effectively for places with the requirement of industrial compressed air.

Temperatures in water-cooled after coolers range between 10 °F and 15 °F, which is beneficial when cooler air is needed. There are several types of water-cooled after-coolers available.

A Shell and Tube After cooler is the most common. There are tubes fitted inside this shell that make up the After cooler. As compressed air passes through the tubes, water passes through the shell in the opposite direction or vice versa. Heat transfers from the compressed air to the water during this process.

water cooled cooler working

Water is formed within the tubes as the compressed air cools. Like an air-cooled cooler, a moisture separator and drain valve are used to remove the moisture.

The compressor air coolers in centrifugal compressors have a massive influence on their efficiency and thus also on their operating costs. They not only affect air compressor cooling but affect air compressor maintenance. To run an industrial air compressor economically over the long term, the compressors’ users must deploy high-quality and technically advanced air cooling systems.

ATLAS COPCO, INGERSOLL RAND AIR COOLER

Our advanced manufacturing technology and the use of a balanced quantity of tubes, in which the compressed air is cooled, enable our high quality air coolers, air compressor intercoolers, air compressor after coolers, following the OEM “donut-type” design, to offer a perfect balance between pressure loss and CTD values.

Centac Coolers

This means that we can not only give our customers a 100% guarantee that our water coolers for centrifugal compressors can be used in their Centac ® compressor without restrictions but also assure them that they have the same or better performance values than the OEM products (Centac cooler) and therefore, efficiency influences the compressor positively in the long term.

Turbo-Air & MSG CENTRIFUGAL COMPRESSOR COOLERS

The intercoolers in Cameron turbo air compressors have a significant influence on their efficiency and thus also on their operating costs. To run a compressor economically over the long term, the compressors’ users must deploy high-quality and technically advanced intercoolers.

Turbo Airtech has precisely fulfilled this customer requirement by providing the best quality Turbo Air compressor coolers currently available in the market for replacement parts that meet OEM specifications.

Turbo Air Compressor Coolers

Our Turbo-Air® Inter coolers offer a perfect balance between pressure loss and performance values.

By that, we can guarantee 100% interchangeability for Cameron Turbo air 3000, Cameron MSG Compressor, other Turbo air coolers and assure our customers that our Inter coolers perform at least as well as the OEM products.

The fact that we manufacture according to the highest standards and a standard warranty of eighteen months on all our Turbo-Air® air coolers witnesses our focus on a product meeting the highest quality standards.

Exploring the Difference Between Intercoolers and Aftercoolers in Air Compressors

When it comes to air compressor cooling applications, understanding the differences between compressor intercoolers and aftercoolers is essential for optimizing system performance. While both devices serve the primary purpose of cooling compressed air, their positions within the system and specific functions differentiate them. An intercooler is typically installed between the stages of a multi-stage compressor, cooling the air before it enters the subsequent compression stage. This process helps to reduce the air temperature, enabling the compressor to operate more efficiently and preventing overheating.

In contrast, a compressor aftercooler is located at the end of the compression cycle, cooling the air immediately after it exits the compressor. This cooling is crucial for reducing the temperature of the compressed air before it enters downstream equipment, thus improving the overall efficiency and reliability of the system. The temperature of compressed air after passing through an aftercooler typically ranges from 10°F to 15°F above the cooling medium’s temperature, whether it be air or water. Understanding these differences is vital for selecting the right cooling solution for specific applications.

Aspect | Intercooler | Aftercooler |

|---|---|---|

Location | Between compressor stages | After the final compression stage |

Function | Cools air before entering next stage | Cools air before downstream equipment |

Temperature | Reduces air temperature significantly | Lowers air temperature to near ambient |

Function and Placement of Intercoolers and Aftercoolers

Understanding the function and placement of intercoolers and aftercoolers is vital in optimizing air compressor systems. Intercoolers are specifically designed to cool the compressed air between stages of a multi-stage compressor, effectively lowering the temperature of the air before it enters the next compression stage. This cooling process helps to minimize the risk of overheating and ensures that the air remains at an optimal temperature for further compression.

On the other hand, aftercoolers are water-cooled and are positioned at the end of the compression cycle. They are designed to cool the hot compressed air immediately after it has exited the compressor. This is crucial for preventing moisture-related issues, as the cooling process leads to the condensation of water vapor, allowing for effective moisture removal. Aftercoolers can be either air-cooled or water-cooled, with water-cooled versions being particularly effective in high heat environments where maintaining a lower air temperature is essential.

In summary, both intercoolers and aftercoolers play vital roles in maintaining optimal temperatures within air compressor systems. By ensuring that the compressed air is cooled effectively at various stages, these devices help to enhance overall system efficiency and reliability while preventing moisture-related damages to equipment.

Frequently Asked Questions

What is air Compressor cooling water requirement?Cooling water requirement vary depending upon many factors; Contact us to determine the precise cooling water requirements for your specific compressor model.