Air compressor leaks can be silent energy thieves, draining your resources and compromising system efficiency. We'll unveil seven expert tricks to detect and fix air compressor leaks, helping you save money and optimize your operations with optimum air flow and reduced air line leaks. Whether you're a seasoned professional or a DIY enthusiast, these proven techniques will empower you to tackle leaks head-on and maintain peak performance.

Compressed air network : Fix Compressed air leaks in air compressors

1. The Sound of Savings: Acoustic Leak Detection for compressed air

Ultrasonic Leak detector kit for compressed air system

One of the most effective ways to detect air compressor leaks is through acoustic leak detection. This method relies on the principle that escaping air produces ultrasonic sound waves. Here's how to implement this technique:

- Invest in an ultrasonic leak detector (prices range from $100 to $1000)

- Scan your compressed air system methodically, focusing on joints, fittings, seals, and hoses.

- Listen for high-pitched hissing sounds that indicate air escaping

- Mark detected leaks for later repair.

Pro tip: Conduct acoustic leak detection during off-hours when ambient noise is minimal for best results.

2. Soapy Solution: The Bubble Test for compressed air leak

For a cost-effective leak detection method, look no further than your kitchen sink. The bubble test is a time-tested technique that's both simple and effective:

- Mix liquid soap with water in a spray bottle

- Apply the solution to suspected leak areas like seals.

- Watch for bubbles forming, indicating air escaping

- Mark bubble locations for repair

Remember: This method works best for accessible areas and smaller leaks.

3. Pressure Drop Analysis for compressed air systems: The Numbers Don't Lie

Monitoring system pressure can provide valuable insights into leak presence and severity. Follow these steps:

- Shut off all air-consuming equipment

- Note the initial system pressure

- Observe pressure drop over a set period (e.g., 10 minutes)

- Calculate leak rate using the formula: Leak Rate = (Pressure Drop / Time) x System Volume

Industry standard: A well-maintained system should not lose more than 5% of its pressure over 10 minutes.

4. Infrared Imaging to identify compressed air leaks: See the Invisible

Thermal imaging cameras can detect temperature differences caused by escaping air, making them an excellent tool for identifying leaks:

- Use an infrared camera to scan your compressed air system

- Look for cool spots indicating air escaping

- Mark detected leaks for repair

Note: While effective, this method requires specialized equipment and training.

5. Data Logging: Track and Trend leak in a compressed air system

Mass Flow meter installation for Air Audit in compressed air system

Implementing a data logging system can help you identify patterns and anomalies in air consumption:

- Install flow meters and pressure sensors throughout your system

- Collect data over time to establish baseline performance

- Analyze trends to identify sudden increases in air consumption, indicating potential leaks

Fact: Studies show that continuous monitoring can reduce compressed air energy costs by up to 30%.

Cost of Compressed air leak

****assumptions used for this table:

- System pressure: 100 psig (typical for industrial systems)

- Electricity cost: $0.10 per kWh

- Operating hours: 8,760 (24/7 operation)

- Compressor efficiency: 18 kW/100 CFM (typical for rotary screw compressors)

The annual cost is rounded to the nearest $10.

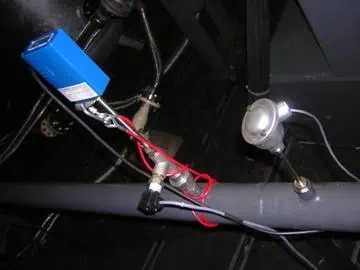

6. DIY Repairs: Quick Fixes to reduce leaks

Once you've identified leaks, it's time to take action. Here are some DIY repair techniques:

- Tighten loose fittings and connections

- Replace worn gaskets and O-rings

- Apply thread sealant to pipe joints

- Repair or replace damaged hoses

Remember: Always follow manufacturer guidelines and safety protocols when performing repairs.

7. Professional Maintenance: The Expert Touch

While DIY repairs can address many issues, some leaks require professional attention:

- Schedule regular maintenance with certified technicians.

- Implement a comprehensive leak detection and repair program

- Consider upgrading older system components that are prone to leaks.

Industry insight: Regular professional maintenance can extend air compressor lifespan by up to 50%.

Frequently Asked Questions:

Q: How often should I check for air compressor leaks?

A: Conduct visual and acoustic inspections monthly, with more comprehensive checks quarterly.

Q: What percentage of air loss is considered normal in an air compressor system?

A: A well-maintained system should have less than 10% air loss due to leaks.

Q: Can air compressor leaks be dangerous?

A: Yes, high-pressure leaks can cause injuries and equipment damage. Always prioritize safety when detecting and repairing leaks.

Q: What is the Leak detection and repair program to detect leaks and prevent air compressor leaks?

A: Leak detection and repair (LDAR) programs for air compressor systems are essential for maintaining efficiency, reducing energy waste, and preventing potential safety hazards in compressed air systems, including line valves.

Conclusion:

By implementing these seven expert tricks to detect and fix air compressor leaks, you're not just saving money – you're investing in the longevity and efficiency of your system. Regular leak detection and repair can significantly reduce energy costs, improve equipment performance, and contribute to a more sustainable operation. Don't let air leaks silently drain your resources; take action today and reap the benefits of a well-maintained compressed air system.

To Know more, contact Turbo Airtech